Advanced Pipeline Inspection Tool Design & Services

Our Bread and Butter

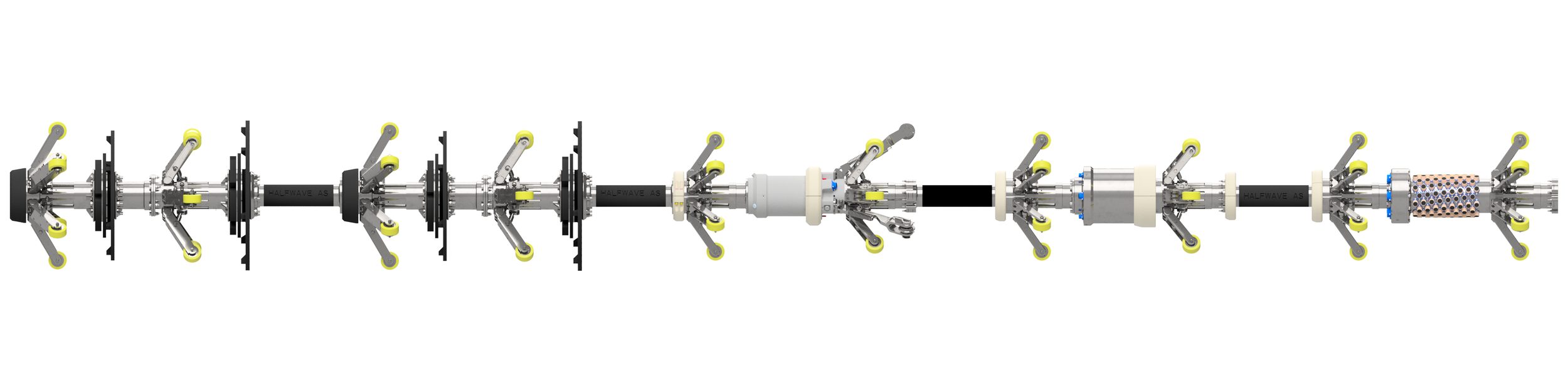

IN-LINE INSPECTION (ILI) TOOL DESIGN

From working within the Oil & Gas industry, D3 specialize in the mechanical design of pipeline inspection tools. We can assist with all aspects of the design, including:

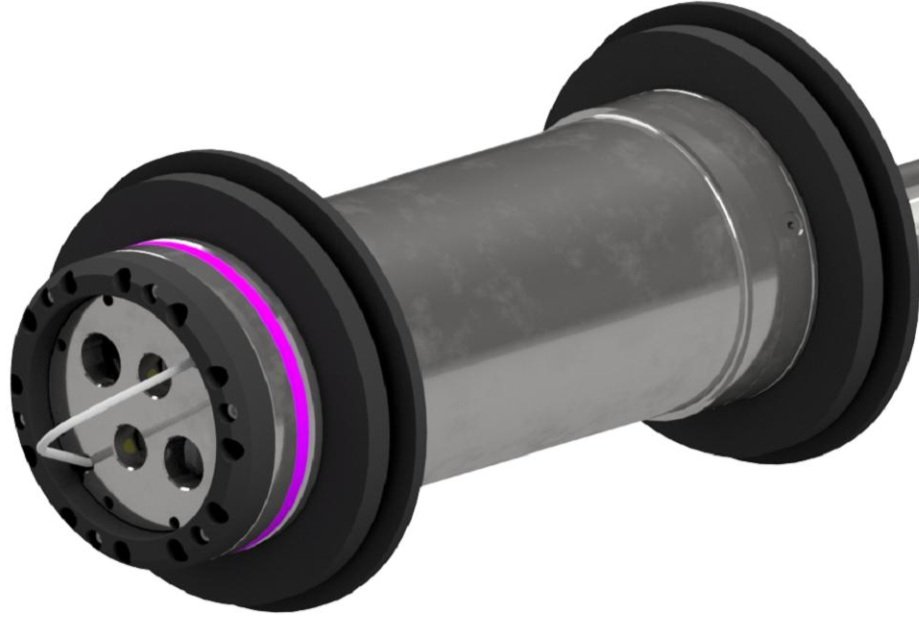

Pressure Vessel design for housing Batteries & Electronics

Specification of sealing elements

Suspension assemblies

Odometer designs

IMU Mapping

Transmitter & tracking device integration

Towbar design

Sourcing and specification of Subsea connectors & harnesses

In Summary, full Mechanical design to ensure the tool can navigate any pipeline.

D3 is home to over 250 years of combined experience in PIG design and have helped a number of clients develop a wide range of tools using various sensor technologies, such as Magnetic Flux Leakage (MFL) and Electro-Magnetic Acoustic Transducers (EMAT) as well as many others ranging from 6 to 56” diameters. We know what to look out for in PIG design having experienced a number of challenging projects in the In-Line Inspection industry including:

Multi-Diameter

Vertical Launch

Wye Passing

Clapper Valve Protection

High Line Pressure

Tight Bend Radii

Onshore and Offshore Launch/Receive

High Flow-rate

Handling Equipment

D3 have also supported the operation and maintenance of PIGs by designing specialist handling equipment such as launchers and manipulator frames, all of which is done to a strict quality in accordance with the relevant codes and standards. We can design & help with the following:

Launcher & receiver systems - hydraulic or chain drive

Cassettes for PIG retrieval

Handling Tray

Pusher Poles & trays

Lifting Cage

Lifting or Pull-out wire/rope

Manipulators

Site Surveying and in-line inspection

Site surveys are crucial to this industry. Time is money, and any difficulties unforeseen early in the early stages will set back projects or even stop completely. Our engineers have had first-hand experience carrying out these surveys to make sure the tools are capable of working under the conditions.

REVIEW OF PIPELINE INFORMATION

Having the uncertainty of problems and failures occur in oil and gas lines can trouble anyone. At D3, we have the experience to review the information provided and consult you on all matters involving this line of work.

Here of some of the aspects, we can review:

Pipeline operating conditions and suitability for inspection

The suitability of launch and receive traps.

The client procedures for pigging

Availability of cleaning and inspection pigs

Using the information provided we can:

Populate a pipeline questionnaire with the available data.

Determine whether a line is suitable for running cleaning and/or inspection pigs.

Specify requirements for cleaning and inspection pigs.

Once we have fully carried what is required, a report can be published detailing the findings of the study.